Abstract

The most recent developments in the field of biobased materials are linked to nanotechnology. In order to enlarge the applications of biopolymers and to increase their performances, a large variety of nanofillers can be effectively used to produce bionanocomposites characterized by specific or multifunctional properties. Polylactide (PLA), a biodegradable polyester obtained from renewable resources, has a keyposition in the market of modern biopolymers, being one of the most promising candidates considered for further developments. The addition into PLA of surface modified nanofillers (organo-modified layered silicates, zinc oxide, graphite derivatives, carbon nanotubes, etc.) is considered as a powerful method for obtaining specific end-use characteristics and major improvements of properties.

The case study highlights recent developments, current results and trends in the field of bionanocomposites based on PLA, taking as a key example the original production of PLA-ZnO nanocomposites assessing multifunctional properties (UV screening, antibacterial activity, etc). Utilization of specifically surface-treated ZnO nanoparticles has been the main requirement to limit PLA degradation during melt-compounding and processing at high temperature. To illustrate the possibility to improve and design the properties of these nanocomposites, a special section is devoted to the effects of addition of masterbatches and selected additives (chain extenders, nucleating agents, plasticizers), recent developments that can pave the way to the larger utilization of these new biomaterials. Moreover, are emphasized the last tendencies strongly evidenced in the case of PLA, i.e., the high interest to diversify its properties and uses by moving from packaging (“disposables”) to technical applications (“durables”).

Keywords

Biopolymers; Poly(lactic acid); PLA; Nanocomposites; Nanofillers; ZnO; Silane; Additives; Multifunctional properties; UV protection; Antibacterial activity.

The “Green” Challenge: Current Interest for New Developments in the Field of Biopolymers and of Polylactide-Based (Nano)Composites

The important increase of demands for utilization of biopolymers is ascribed to a huge number of factors including the consumer requests for more environmentally sustainable products, development of new bio-based feed stocks, consideration of recycling options, increasing of price and of restrictions for the use of polymers with high “carbon footprint” of petrochemical origin, particularly in such applications as packaging, automotive, electrical and electronics industry, etc. [1–3]. Moreover, according to a recent report published by BCC Research (Global Markets and Technologies for Bioplastics (PLS050B) – February 2019), for the global bioplastics market (bio-based/non-biodegradable and biodegradable) a compound annual growth rate (CAGR) of 11.7% is estimated for the period 2018–2023.

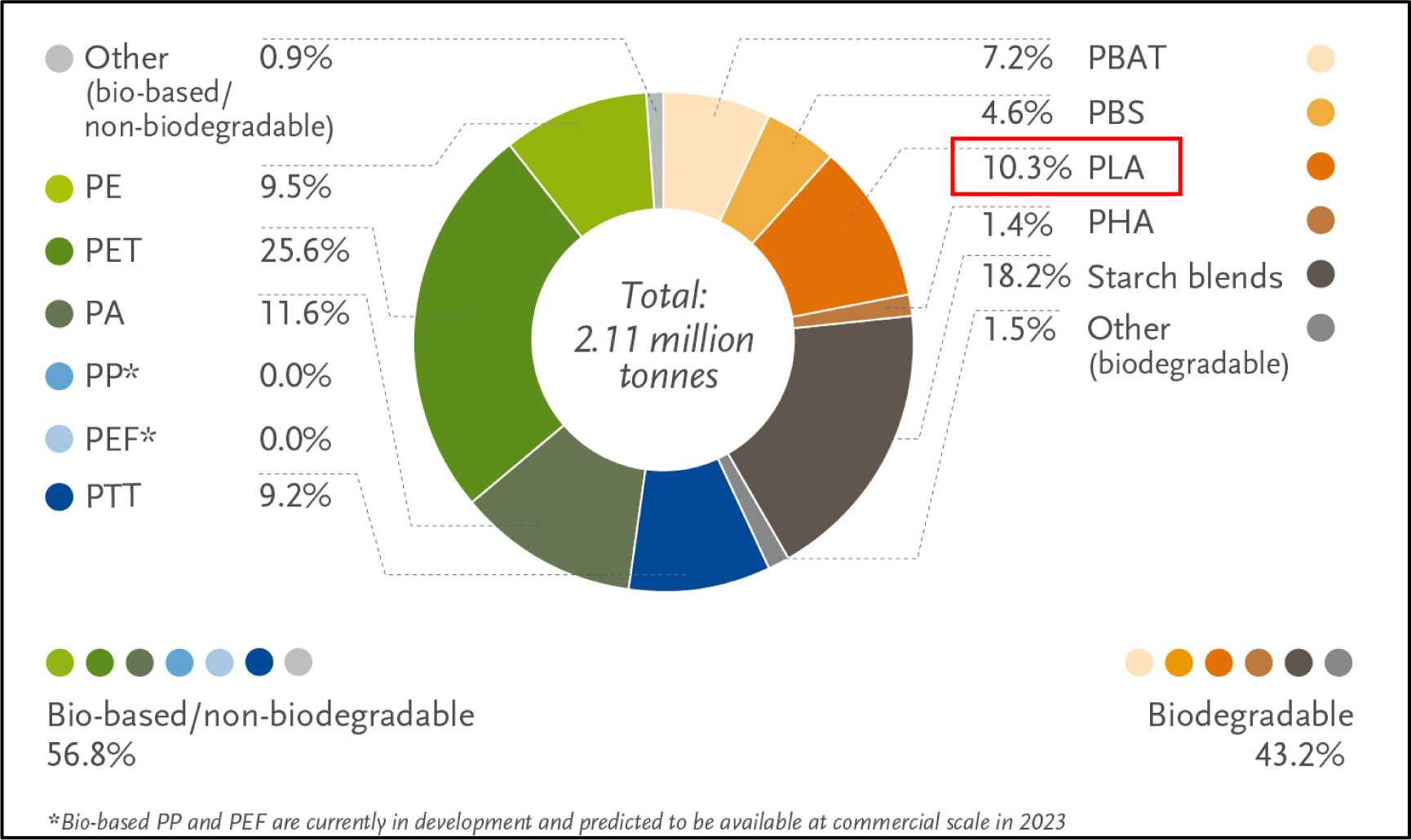

From the category of biopolymers (Figure 1), poly (lactic acid) or polylactide (PLA) belongs undoubtedly to the most promising candidates considered for further developments, because of its renewability, biodegradability, biocompatibility, good thermal and mechanical properties. Following the current technical progress, PLA grades produced from lactide monomers of high optically purity are characterized by melting temperatures in the range 170–180 °C, while those of PLA stereocomplexes can be even higher than 220 °C [4]. Regarding the mechanical properties, PLA is characterized by a noticeable high tensile strength (50–70 MPa) and rigidity (i.e. Young’s modulus is given in the range 2000–3000 MPa), but it also has some drawbacks, e.g., the brittle behaviour and low ductility, therefore PLA modification is highly considered to have improved characteristics [2,5].

Figure 1. Global production capacities (2018) for bioplastics by polymer type (adapted, source European Bioplastics, nova-Institute (2018))

PLA is currently receiving a great attention for conventional utilization such as packaging materials, as well as production of textile fibers. As this biodegradable polyester is considered as an important alternative for the partial substitution of polymers of petrochemical origin, there is therefore a strong demand to extend the range of PLA properties [5]. The last tendencies show as evidence that improved PLA products and new grades with higher added value are especially required for engineering applications (transportation, electronic and electrical devices, mechanical and automotive parts, etc.). Consequently, for a larger utilization the profile of PLA properties is tuned up by combining the polyester matrix with reinforcing fibres, micro- and nano-fillers, flame retardants, impact modifiers, plasticizers, other additives of speciality. Furthermore, in order to produce more performant “bio-based” products, there is also the growing trend for the production of blends of biopolymers [6] with petrochemical-based plastics (NB: in the absence or presence of nanofillers [7,8]) and this is seen as a possibility to extend their market as durable products/materials in cars, cell phones, and many other applications.

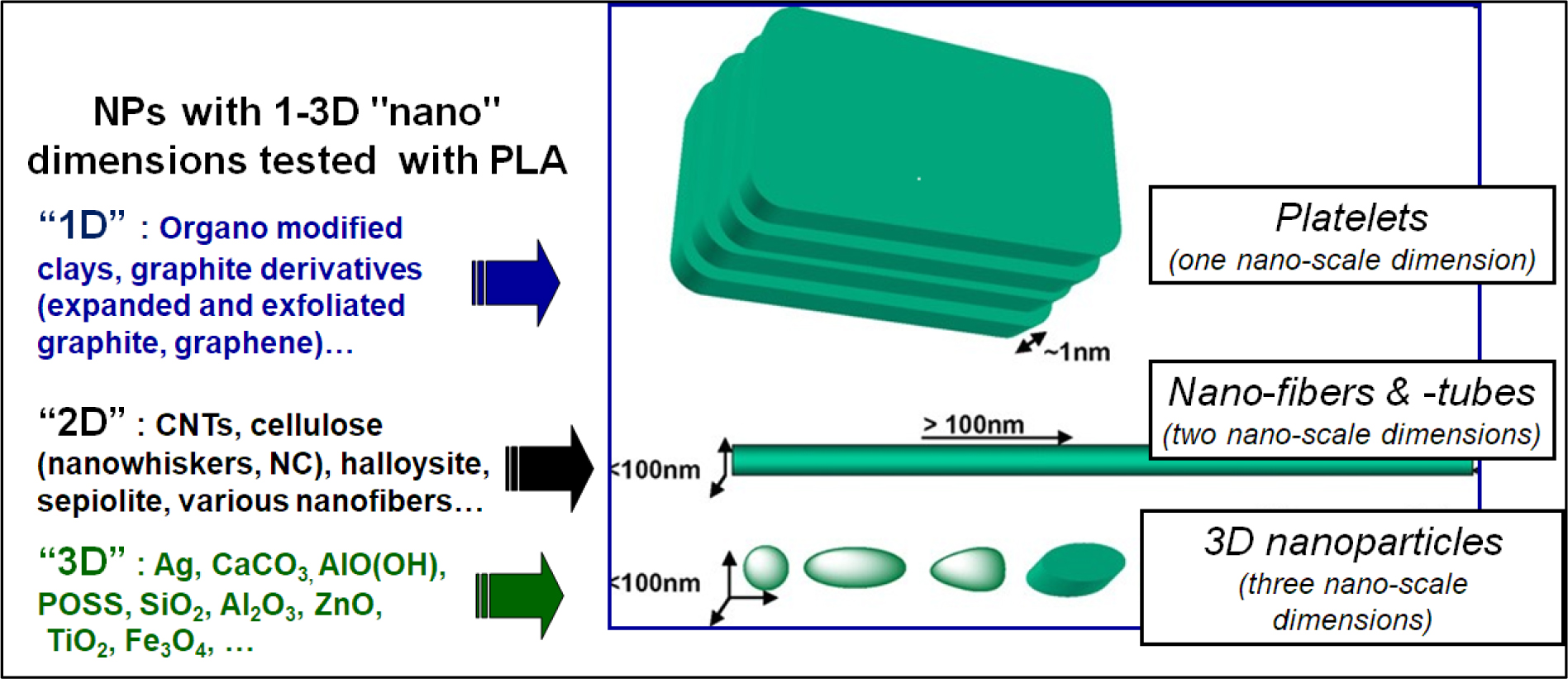

On the other hand, in relation to the production of PLA nanocomposites, it is important to remind that the polymer-based nanocomposites are known to be a radical alternative to conventionally micro-filled polymers due to their improved characteristics (high strength and rigidity, thermal stability, barrier properties, flammability resistance, electrical and optical, or other specific properties) obtained at low nanofiller loadings as low as 1–5 wt.%. The transition from micro- to nanoparticles yields dramatic changes in the properties of polymers since many important chemical and physical interactions are governed by the properties of high surface nanoscale-dispersed fillers having different morphologies (Figure 2). Thus, the addition into PLA matrix of adequately modified nanofillers with 1–3D nano-dimensions (e.g., organo-modified layered silicates (OMLS), silver, zinc oxide (ZnO), graphite/graphene derivatives, carbon nanotubes (CNT), silica, polyhedral oligomeric silsesquioxanes (POSS), magnetite, (bio) nanoparticles such as starch and cellulose nanocrystals, etc.) is considered as an interesting approach that can lead to major improvements of PLA characteristic features (mechanical, thermal, barrier, etc.) [2]. Furthermore, these nanocomposites can be characterized by specific end-use properties such as anti-UV and anti-bacterial, antistatic to conductive electrical characteristics, enhanced wear resistance, fire-retardancy, superparamagnetic properties, increased biodegradability, higher crystallization speed, and so on. Still, it is assumed by us that especially the “durable” applications are requiring more and more new high-performance materials/nanocomposites showing multifunctional properties.

Figure 2. Nanofillers with “1–3D” nano-dimensions that are currently used to produce PLA nanocomposites (adapted from [2,10])

As it comes out from the State of the Art, as well as by considering the R&D topics conducted by Authors’ research group, many developments related with the field of nanotechnology are focused on the original production of novel bionanocomposites such as based on bio-sourced and biodegradable PLA [2,9]. Furthermore, designing polymer nanocomposites with multifunctional properties can be considered as one of the last key tendencies. For better illustration of these trends, selected results relied upon the original production of innovative nanocomposite materials using PLA as polyester matrix and ZnO as nanofiller, are summarized hereinafter as representative case study.

PLA-ZnO Nanocomposites with Multifunctional Properties, a Case Study

ZnO is well-known environmentally friendly and multifunctional inorganic filler characterized by effective antibacterial function and intensive ultraviolet absorption [11,12]. Until now, ZnO as well as other zinc-related compounds have been successfully utilized as effective catalysts for lactide polymerization and in “unzipping” depolymerization of PLA that allows its chemical recycling. In this context, it is reasonable to expect that the dispersion of untreated ZnO nanoparticles within PLA matrix will generate its dramatic degradation, especially at high temperature, e.g., along with its melt-processing [13]. Clearly, this is the main reason explaining the low number of studies regarding the production of PLA-ZnO nanocomposites using the melt-compounding approach.

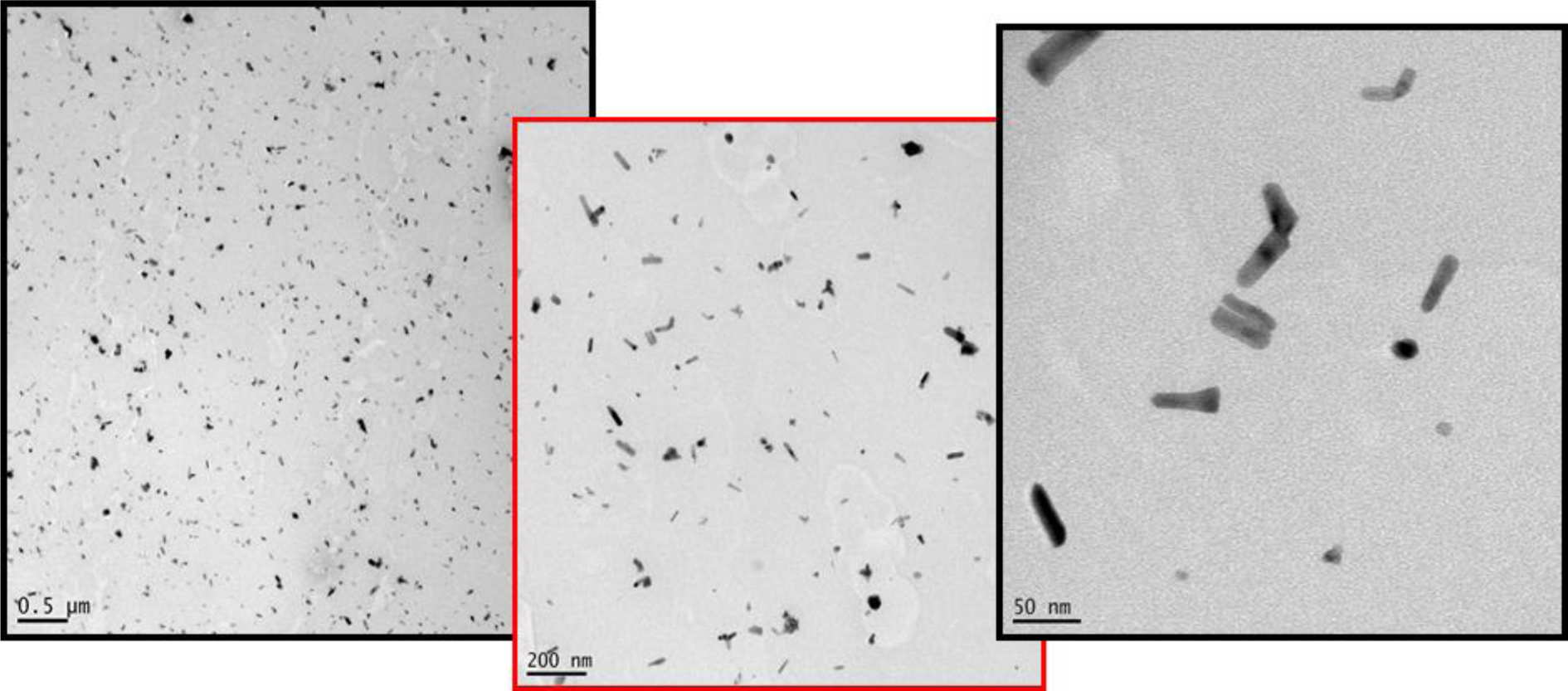

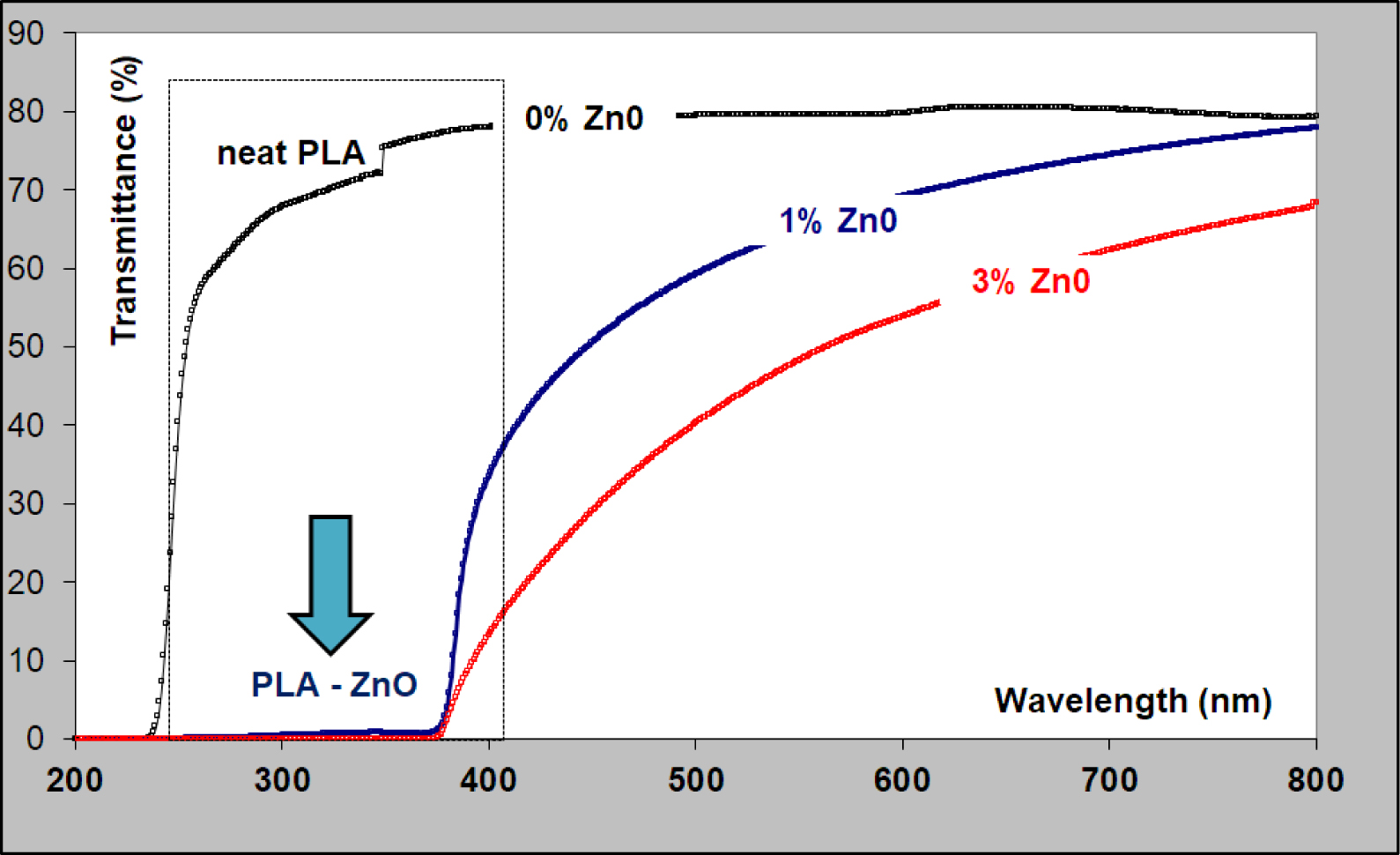

Utilization of specific surface treated ZnO nanoparticles, a main requirement

The first objective was to make PLA matrix less susceptible to the catalytic action of ZnO nanoparticles (NPs) during melt-compounding and subsequent film/fiber or injection molding processing. Our studies have indeed revealed that the addition of untreated ZnO (NPs with a morphology like “rods” of length up to 100 nm, diameter of ~15–30 nm) leads to the dramatic degradation of PLA matrix. Thus, various filler surface treatments with selected additives (stearic acid, stearate derivatives, (fatty) amides, etc.) were tested but they have shown low effectiveness. Contrary to the untreated nanofiller, surface-treated ZnO by a specific silane containing lipophilic caprylyl groups (i.e., 4% triethoxycaprylylsilane) was found to lead to nanocomposites characterized by noticeable thermo-mechanical performances (e.g., tensile strength in the interval 55–65 MPa), while the onset of thermal degradation was significantly increased by 20 to 40 °C with respect to the samples containing 1–5% non-treated nanofiller [13]. Such improvements in view of their utilization in production of films or fibers, injection/extruded products, etc, were ascribed to the effect of –Si-O-Si-O- layers, which cover the surface of nanofiller and behave as barrier, effectively limiting the catalytic degradation effect of ZnO on the surrounding polyester matrix. Furthermore, as highlighted by TEM (Transmission Electron Microscopy) images (Figure 3), the surface coating by silane allows for a finer dispersion and distribution of ZnO nanoparticles through the PLA matrix. Regarding the specific end-use applications of PLA-ZnO (silane-treated) nanocomposites, they show multifunctional properties such as antibacterial effects (against both gram-positive and gram-negative bacteria), barrier and UV protection [13,14]. Indeed, films of PLA-ZnO nanocomposites assess an effective UV protection (Figure 4) evidenced on an amount of nanofiller as low as 1%. On the other hand, mats of PLA-ZnO nanocomposite fibers display a faster antibacterial action as evidenced at 3% ZnO loading (Table 1)[13,15] due to the high surface area of the related fibers. Following these promising results, higher quantities of nanocomposites were produced by melt-compounding PLA (various molecular weights) with ZnO(s) (silane-treated) using laboratory twin-screw extruders and tested for the first time with promising results to produce films and fibers. Lastly, we assume that the melt-blending approach successfully developed by us to produce these specific bionanocomposites can have larger applicability with respect to other techniques, such as solvent casting or 3D-printing method.

Figure 3. TEM pictures at different magnifications of PLA -1% ZnO nanocomposites obtained by melt-compounding (twin-screw extruders) attesting for the good nanofiller dispersion within PLA matrix.

Figure 4. UV-vis spectra of PLA- ZnO(s) (silane-treated) films compared to the neat PLA proving the total UV screening in the case of nanocomposites.

Table 1. Results of antibacterial tests (24h) for knitted fabrics (PLA and PLA/3% ZnO) on: (a) gram-positive and (b) gram-negative bacteria, [13]

|

Type of bacteria |

Sample |

Average (log CFU) |

Growth |

Antibacterial activity (A) |

|

|

0 h |

24 h |

||||

|

a) Staphylococcus aureus gram-positive bacteria |

PLA (C) |

4.69 |

6.90 |

F = 2.21 |

(A = F – G) |

|

PLA/3% ZnO |

4.66 |

2.57 |

G = -2.09 |

||

|

b) Klebsiella pneumoniae gram-negative bacteria |

PLA (C) |

4.66 |

7.63 |

F = 2.97 |

A = 6.67 |

|

PLA/3% ZnO |

4.70 |

1.00 |

G = -3.70 |

||

Abbreviation: CFU = colony forming units; A = antibacterial activity; C= control/reference sample; F = (logC24 − logC0) and G = (logT24 − logT0) represent respectively the growth values in presence of neat PLA sample (control/without ZnO), while G corresponds to the growth values in presence of treated samples (PLA- 3% ZnO nanocomposites).

(NB: Antibacterial activity >3.0 means reduction in bacteria number > 99.9 %)

Recent progress in designing PLA-ZnO nanocomposites with tailored properties

In the great majority of cases, the properties of polymer nanocomposites can be improved, designed and “tailored” to answer to the requirements of end-use applications. As mentioned before, PLA-ZnO nanocomposites were successfully tested in the production of fibers, films or other items, showing multifunctional properties (protection against UV radiation, antibacterial, barrier, etc.). However, for some specific requests they can have some limitations (e.g., low ductility and crystallization rate, relatively low stability at high temperature and long residence time), which can affect their processing and final performances of products.

It is also worth recalling that PLA is very sensitive to temperature, shear and hydrolysis during melt-processing. Besides, in many cases the mixing of PLA with additives and nanofillers is followed by the important drop of molecular weights, together with the loss of thermal, rheological and mechanical properties. Unfortunately, in the case of industrial applications and especially at high processing temperature and/or long residence time, PLA and its nanocomposites do not show the advanced stability that can be required by end users, since the decrease of molecular parameters can strongly affect their melt-fluidity and processing ability, thermal and mechanical properties. Therefore, the control of thermal degradation of PLA-ZnO nanocomposites represents a major challenge.

Utilization of chain-extenders: To improve the processing and performances of PLA nanocomposites such as their stability at high temperature, the addition of selected chain-extenders (CE) can be considered [16]. Indeed, some recent studies revealed that the co-addition of nanofiller (ZnO) and of epoxy functional styrene-acrylate oligomeric CE (Joncryl® ADR 4300F) leads to significant enhancements of the properties (molecular, rheological, thermal, etc.) of PLA-ZnO nanocomposites. As one key result, adding 1% CE into nanocomposites the PLA molecular weights are found to be nearly twofold higher. Moreover, as it is shown in Table 2 the samples containing CE were characterized by a higher T5% (the onset of thermal degradation), while the isothermal tests at high temperature (220°C and 240°C) proved a very significant gain in thermal stability at longer residence time [16]. CE addition also plays a key role refining the processability by extrusion of relatively highly filled nanocomposites (e.g., with 3–5% ZnO) to produce films. This is ascribed to the rheological improvements, i.e., low MFI, increased viscosity and melt-strength in the molten state. The good dispersion/distribution of ZnO nanoparticles at nanoscale level was evidenced once more by TEM, whereas the specific end-use properties following ZnO addition are once more confirmed (e.g., UV protection).

Table 2. Effects of CE addition on initial decomposition temperature (T5%) and max. decomposition temperature (Td) of PLA–ZnO(s) nanocomposites as determined by TGA (under airflow, 20 °C/min)

|

Sample |

Temperature of 5% weight loss (T5%), °C |

Temperature of max. rate of degradation (Td), °C |

|

1% ZnO(s) |

325 |

361 |

|

1% ZnO(s) /0.5% CE |

330 |

367 |

|

1% ZnO(s) /1% CE |

336 |

365 |

|

3% ZnO(s) |

313 |

354 |

|

3% ZnO(s) /0.5% CE |

317 |

360 |

|

3% ZnO(s) /1% CE |

325 |

361 |

|

5% ZnO(s) |

307 |

353 |

|

5% ZnO(s) /1% CE |

318 |

357 |

PLA- (20–40)% ZnO as masterbatch: To offer more flexibility to the potential users in relation to the choice of loading in ZnO NPs and to lead to more competitive products by better control of PLA molecular weights and processing, the effects of masterbatch (MB) addition on the properties of PLA nanocomposites have been studied [17]. First, highly filled PLA-ZnO MBs containing up to 40% silane-treated ZnO(s) have been successfully produced by melt-compounding. Subsequently these MBs have been used for producing films containing up to 3% ZnO(s) nanofiller. A shorter residence time of PLA in presence of ZnO (recognized for its degrading effect) using the MB approach is seen as the way to lead to nanocomposites (products) characterized by improved properties. Some key-advantages conferred by utilization of MB techniques in the production of PLA-ZnO(s) nanocomposite films are mentioned hereafter.

- Processing: a better extrusion ability is typically observed by processing blends of virgin PLA and MBs (PLA- 40% ZnO(s)), which is ascribed to a higher viscosity of the molten polymer and to the lower degradation of PLA during extrusion (better molecular parameters)

- Thermal properties: the films obtained via the MB approach show improved thermal parameters (the onset of temperature of degradation (T5%) is increased by ca. 20 °C) by comparing to those obtained using the traditional two-step method to produce films (i.e., melt-compounding to obtain nanocomposites, and then, reprocessing by extrusion to produce films)

- Morphology: remarkable quality of ZnO dispersion trough PLA matrix even using highly filled MBs (i.e., 40% ZnO(s)).

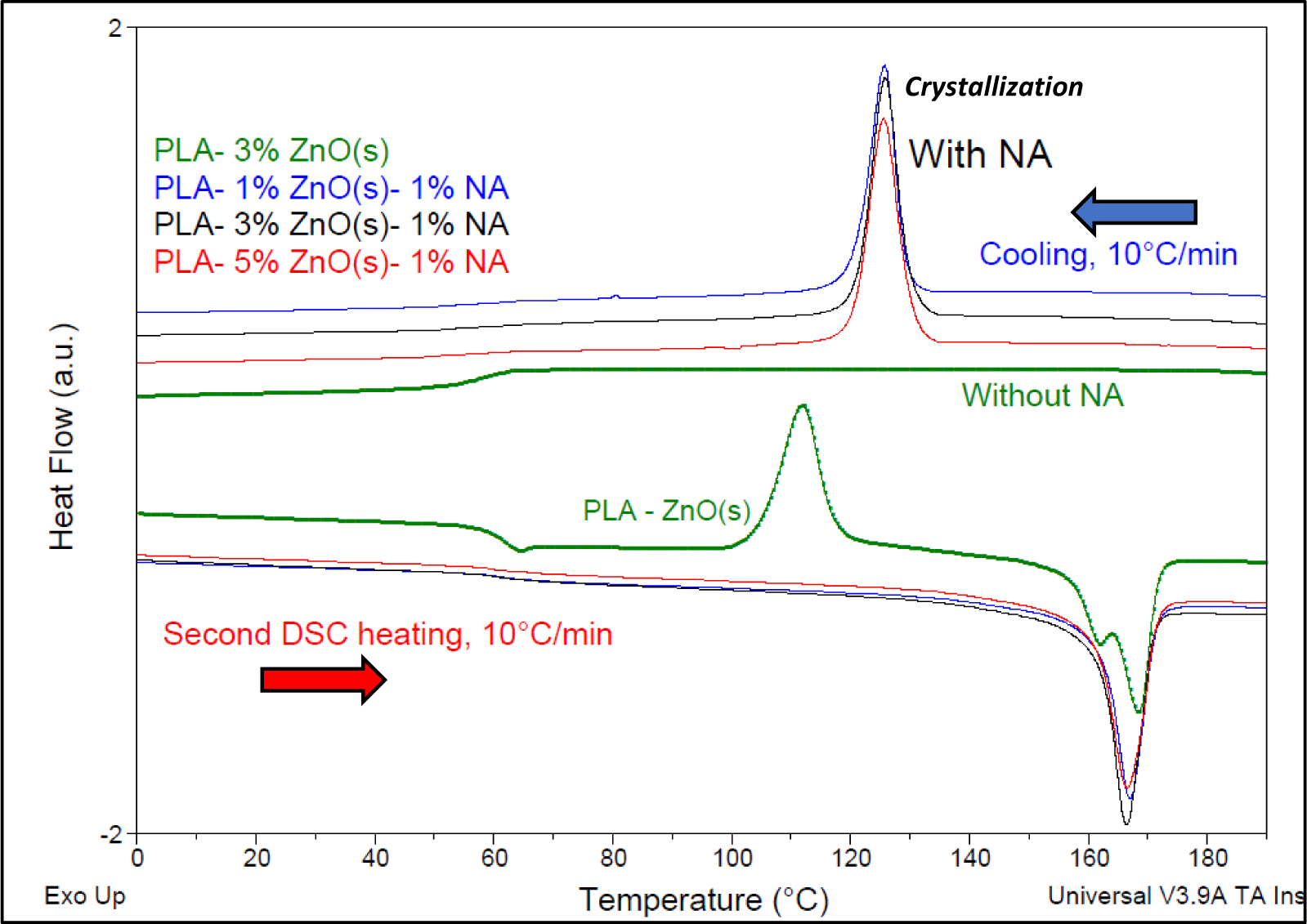

PLA-ZnO nanocomposites with improved crystallization ability and increased ductility: It is important to remind that PLA shows several drawbacks such as the brittle behavior, high sensitivity to hydrolysis and low crystallization rate. Particularly, the low crystallization extent of PLA represents a major limitation with respect to many other thermoplastics. For instance, under usual injection molding conditions, i.e., at high cooling rates, mostly amorphous items can be obtained from most commercially available PLA grades. In fact, this is a kind of “Achilles’ heel” limiting PLA use in high-performance applications [18]. On another side, the degree of crystallinity does represent an essential parameter to control the degradation rate of PLA as well as its thermal resistance, optical, mechanical and barrier properties. Thus, to complete the panel of properties of PLA-ZnO nanocomposites by producing new formulations characterized by significant improvements in crystallization properties, the addition of different nucleating agents (NA) has been considered. A remarkable increase of the degree of crystallization and concomitant important enhancements in the rate of crystallization can be obtained by adding 0.5–1% phenylphosphonic acid zinc (PPA-Zn) as NA in PLA-ZnO(s) nanocomposites. Undeniably, by adding PPA-Zn the degree of crystallinity of PLA as determined by Differential Scanning Calorimetry (DSC) proved to be dramatically increased in the range 40–50% with respect to values of only 3% for nanocomposites without any NA. Furthermore, only nanocomposites containing NA show clear-cut crystallization properties during DSC cooling from the molten state (Figure 5).

Figure 5. DSC analyses of PLA – ZnO(s) nanocomposites to show the effectiveness of nucleating agent (NA) addition on PLA crystallization properties (DSC method: cooling by 10°C/min from the molten state, followed by a second DSC heating by 10°C/min)

On the other hand, for applications requiring high ductility and impact resistance, addition of plasticizers such as tributyl citrate (TBC, 15 – 20%), is beneficial to tailor their mechanical properties (i.e., decrease of rigidity/Young’s modulus, increase of strain at break, etc.). Accordingly, it means that by finely tuning their formulation, PLA-based bionanocomposites can be delivered with desired mechanical properties (Table 3), going in the case of PLA-ZnO(s) nanocomposites from higher strength and rigidity, to materials with lower stiffness and increased ductility/strain at break [19].

Table 3. Effect of selected additives on the mechanical properties of PLA – 3% ZnO(s) nanocomposites (specimens type V, ASTM D638, v = 1 mm/min; abbreviations: CE = chain extender; NA = nucleating agent; TBC = Tributyl citrate (plasticizer))

|

Sample |

Max. tensile strength, MPa |

Young’s modulus, |

Strain at break, |

|

PLA- 3% ZnO |

62 (± 1) |

2300 (± 150) |

4.9 (± 0.2) |

|

PLA- 3% ZnO- 1% CE |

65 (± 2) |

2250 (± 250) |

6.6 (± 3.0) |

|

PLA- 3% ZnO- 1% NA |

66 (± 2) |

2600 (± 100) |

4.2 (± 0.4) |

|

PLA- 3% ZnO- 15% TBC |

33 (± 2) |

1850 (± 100) |

200 (± 30) |

Synergies of properties and realization of hybrid nanocomposites

By considering the recent trends, it is noteworthy mentioning that another direction of great attention in the field of bionanocomposites is the combination of nanofillers of different nature/morphology to produce hybrid nanocomposites with improved/multifunctional end-use characteristics. In this goal, ZnO (recognized for its photocatalytic properties [20] and antibacterial activity) can be combined with other NPs, e.g., silver nanoparticles [21, 22] to improve the antibacterial effects, while other properties such as UV screening will be preserved. Again, fine dispersion of the nanoparticles remains a challenge for advanced performances, whereas new experimental pathways comprising different synergies (e.g., between ZnO and other NPs), combinations of NPs and special techniques of production can undoubtedly increase the potential of these nanocomposites as “green” products for new applications.

As preliminary conclusion in relation to this case study, these selected examples are revealing that following the specific surface treatment of NPs (i.e., ZnO) and by addition of selected additives it is possible to produce PLA-based nanocomposites tailored with multifunctional properties (UV screening, antibacterial activity, barrier properties, self-cleaning…). As novelty, the production of PLA-ZnO nanocomposites via melt-compounding open the way to environmentally friendly new products that can be of further extrapolated at larger scale to produce fibres, films, other products (Figure 6). The possibility of chemical recycling at the end-use life (ZnO as catalyst) and the biodegradation as option are completing the panel of properties of these bionanocomposites.

Figure 6. Semi-finished products (films, plates, fibers) produced at laboratory scale using the new PLA-ZnO nanocomposites.

Concluding Remarks and Future Prospects

To summarize, the following conclusions can be drawn in relation to the current trends in the field of biopolymers and particularly for the designing of PLA bionanocomposites with specific end-use properties:

- High interest for utilization of biopolymers (PLA as one key-candidate) and promotion of environmentally friendly products obtained in the field of nanotechnology.

- In response to the demand for enlarging PLA applications/properties, a large variety of nano-fillers (1–3D) can be effectively used to produce novel bionanocomposites with specific or multifunctional properties.

- The adequate surface treatment of NPs is the key-solution for increased performances. Specific ZnO silanization was necessary to limit the decrease of PLA molecular and thermo-mechanical parameters, while the nanocomposites show excellent nanofiller dispersion and specific end-use characteristics.

- PLA-ZnO nanocomposites: “tailored” formulations obtained by melt-compounding are available for extrapolation at larger scale. By considering the specific end-use properties, these nanocomposites are interesting as new materials for special packaging, textile products, electrical/electronic and household appliances, etc.

By considering the last information from the State of the Art, it is very clear that nanotechnology can further lead to an important technical progress in the field of bio-based materials. At the moment, some expectations are not totally confirmed, thus it can be assumed that this can be only a problem of time by considering that the industrial production of some biopolymers (e.g., PLA) is of recent date. However, in the case of biopolymers that have been initially considered for their biodegradability, it will be a hard work to attest their utilization in durable applications, because this needs a change of perception, that must follow the current state of the development. In this context, it is easier to implement the “nanotechnology” concept by using polymer matrices that have confirmed in the past as materials of high performance (e.g., engineering polymers) and having good resistance to aging. By considering the restrictions connected to the utilization of petrochemical polymers with high carbon footprint, association of nanotechnology and biopolymers can be successfully valorized on the market. Nevertheless, new bionanocomposites (such as the ones based on PLA) are very promising materials since they could show improved performances (high strength and rigidity, thermal stability, low flammability, antistatic to conductive electrical characteristics, anti-UV or antibacterial protection…) while maintaining the specific properties of biodegradability of the polymer matrix. Furthermore, it can be expected an increased interest for the implementation of new PLA grades in engineering (durable) applications without excluding the conventional uses, such as packaging materials, as well as production of fibers. As a final point, it can be assumed that the new bionanocomposites characterized by tailored or multifunctional properties can represent an excellent opportunity for the larger application of biopolymers.

Acknowledgments

Authors thank the Wallonia Region, Nord-Pas de Calais Region and European Community for the financial support in the frame of the IINTERREG IV – NANOLAC project. They also thank to Anne-Laure Dechief and Oltea Murariu for contribution in realization of experiments and all collaborators for helpfully discussions. Authors thank the European Commission and Wallonia Region (FEDER program 2014–2020) for the financial support in the frame of PROSTEM project (Biofunctional microcarriers for production and application at large scale of stem cells) and MACOBIO project (Low carbon footprint).

References

- Murariu M, Laoutid F, Dubois P, Fontaine G, Bourbigot S, et al. (2014) Chapter 21 – Pathways to Biodegradable Flame Retardant Polymer (Nano)Composites. In Polymer Green Flame Retardants, Papaspyrides, C.D.; Kiliaris, P., Eds. Elsevier: Amsterdam 709–773.

- Raquez JM, Habibi Y, Murariu M, Dubois P (2013) Polylactide (PLA)-based nanocomposites. Progress in Polymer Science 38: 1504–1542.

- Babu RP, O’Connor K, Seeram R (2013) Current progress on bio-based polymers and their future trends. Prog Biomater 2: 8.

- Tsuji H (2016) Poly(lactic acid) stereocomplexes: A decade of progress. Advanced Drug Delivery Reviews 107: 97–135.

- Murariu M, Dubois P (2016) PLA composites: From production to properties. Advanced Drug Delivery Reviews 107: 17–46.

- Nofar M, Sacligil D, Carreau PJ, Kamal MR, Heuzey MC (2019) Poly (lactic acid) blends: Processing, properties and applications. International Journal of Biological Macromolecules 125: 307–360.

- Ebadi-Dehaghani H, Khonakdar HA, Barikani M, Jafari SH (2015) Experimental and theoretical analyses of mechanical properties of PP/PLA/clay nanocomposites. Composites Part B: Engineering 69: 133–144.

- Ploypetchara N, Suppakul P, Atong D, Pechyen C (2014) Blend of Polypropylene/Poly(lactic acid) for Medical Packaging Application: Physicochemical, Thermal, Mechanical, and Barrier Properties. Energy Procedia 56: 201–210.

- Basu A, Nazarkovsky M, Ghadi R, Khan W, Domb AJ (2017) Poly(lactic acid)-based nanocomposites. Polymers for Advanced Technologies 28: 919–930.

- Kumar AP, Depan D, Singh Tomer N, Singh RP (2009) Nanoscale particles for polymer degradation and stabilization—Trends and future perspectives. Progress in Polymer Science 34: 479–515.

- Shankar S, Wang LF, Rhim JW (2018) Incorporation of zinc oxide nanoparticles improved the mechanical, water vapor barrier, UV-light barrier, and antibacterial properties of PLA-based nanocomposite films. Materials Science and Engineering: C 93: 289–298.

- Kim I, Viswanathan K, Kasi G, Sadeghi K, Thanakkasaranee S, et al. (2019) Poly(Lactic Acid)/ZnO Bionanocomposite Films with Positively Charged ZnO as Potential Antimicrobial Food Packaging Materials. Polymers 11: 1427.

- Murariu M, Doumbia A, Bonnaud L, Dechief AL, Paint Y, et al. (2011) High-Performance Polylactide/ZnO Nanocomposites Designed for Films and Fibers with Special End-Use Properties. Biomacromolecules 12: 1762–1771.

- Pantani R, Gorrasi G, Vigliotta G, Murariu M, Dubois P (2013) PLA-ZnO nanocomposite films: Water vapor barrier properties and specific end-use characteristics. European Polymer Journal 49: 3471–3482.

- Doumbia AS, Vezin H, Ferreira M, Campagne C, Devaux E (2015) Studies of polylactide/zinc oxide nanocomposites: influence of surface treatment on zinc oxide antibacterial activities in textile nanocomposites. Journal of Applied Polymer Science 2015: 132.

- Murariu M, Paint Y, Murariu O, Raquez JM, Bonnaud L, et al. (2015) Current progress in the production of PLA–ZnO nanocomposites: Beneficial effects of chain extender addition on key properties. Journal of Applied Polymer Science 2015: 132.

- Murariu M, Benali S, Paint Y, Bonnaud L, Dubois P (2015) In Adding value in production of PLA – ZnO nanocomposites through novel techniques, Conference proceedings MdC, Mons, Belgium.

- Murariu M, Dechief AL, Ramy-Ratiarison R, Paint Y, Raquez JM, et al. (2015) Recent advances in production of poly(lactic acid) (PLA) nanocomposites: a versatile method to tune crystallization properties of PLA. Nanocomposites 1: 71–82.

- Murariu M, Benali S, Raquez JM, Dubois P (2017) In Designing the properties of PLA – ZnO nanocomposites for new applications, Conference proceedings BIOPOL, Mons, Belgium.

- Therias S, Larché JF, Bussière PO, Gardette JL, Murariu M, et al. (2012) Photochemical Behavior of Polylactide/ZnO Nanocomposite Films. Biomacromolecules 13: 3283–3291.

- Shameli K, Ahmad MB, Yunus WMZW, Ibrahim NA, Rahman RA, et al. (2010) Silver/poly (lactic acid) nanocomposites: preparation, characterization, and antibacterial activity. Int J Nanomedicine 5:573–579.

- Chu Z, Zhao T, Li L, Fan J, Qin Y (2017) Characterization of antimicrobial poly (lactic acid)/nano-composite films with silver and zinc oxide nanoparticles. Materials 2017: 10.