Summary

A serious environmental problem, which affects most of the countries for years, is the massive use of tires, which once used, generate large stocks of waste material. A common method to process these used tires goes through crushing, in which the fiber, steel and rubber obtained from the crushing process are separated. This article affects the reuse of rubber obtained from these tires, also called GTR (Ground Tires Rubber), by mixing with various thermoplastic polymeric compounds, in order to improve some of its mechanical and structural properties, and at the same time, give exit to these surpluses that cause already used tires. For this purpose, the article analyzes the mechanical-structural properties of seven common thermoplastic polymers, which mixed with the GTR ) for a single particle size (p <200µm). could be useful in industrial processes. From the results obtained, it follows that this proposal is valid, in lower percentages of GTR (5% -10% of GTR) analyzed (from 5% to 70% of GTR).

Keywords

GTR, Recycling, Reuse, Composite, Microstructural Analysis, Mechanical Properties, Polymeric compounds, thermoplastics, Scanning Electronic Microscopy

Introduction

The environmental problem of the accumulation of used tires (GTR) [1–3] has driven the efforts of the scientific community to seek solutions for the recovery and reuse of these tires. In general, a thermoplastic or thermosetting polymer acts as a matrix and the elastomer (GTR) acts as a dispersed phase [4–6] or reinforcement. As in other two-phase polymer mixtures, in these compounds [7–8] the interfacial compatibility between components is basic to achieve the desired mechanical properties. In the case of recycled elastomers, the expected compatibility is low, so it is intended to increase this compatibility by reducing the degree of GTR crosslinking by devulcanization [9–11], also observing significant changes in the properties when we vary the particle size of GTR [12] reinforcement. The use of these recycled tires as reinforcements in composite materials has been extensively studied in numerous works of physical characterization of polymers with GTR particles, but in this case, a complete comparative mechanical and structural analysis of these properties in different compounds has been performed [13–15], quantifying how the presence of GTR in the polymer matrix modifies its mechanical behavior. The size of the GTR particles, in this work, is restricted to p <200μm. The aim is to analyze what percentage of GTR can be added to the different polymeric matrix polymers (PVC, EVA, HDPE, PP, PA, ABS and PS) analyzed, in order to keep their mechanical properties and structure of the polymers within acceptable values [16 -18]. For this purpose, several concentrations of Polymer / GTR (from 0% to 70% in GTR) have been analyzed, with one particle size, always with the GTR as a reinforcing agent. Some authors such as [19 -20] have observed that the presence of carbon black as reinforcement in composites increases the mechanical properties. Composite materials are heterogeneous, and their properties depend on the quantity, size and shape of the reinforcement, as well as other factors such as their preparation, or their compatibility.

[21] have studied different PVC samples with different compositions and varying proportions of additives such as carbon black (CB). Studies show that PVC with CB produces compounds that improve mechanical properties. In summary, the objectives of this research are to analyze and compare the mechanical-structural behavior of different composite materials obtained by mixing different polymers with different percentages of GTR (up to 70%) and, demonstrating that although the addition of GTR normally excludes industrial applications with high mechanical requirements, that pure polymers do provide, if they could, instead, be part of the recycling solution in many other industrial applications.

Materials And Methods

Materials

The following polymers have been used in this study: Polyvinyl Chloride (PVC); High density polyethylene (HDPE); The ethylene vinyl acetate (EVA) copolymer especially used for the production of extrusion films and coatings (18% vinyl acetate and 82% ethylene); Polypropylene (PP); Acrylonitrile butadiene styrene (ABS) white, consisting of 30% acrylonitrile, 20% butadiene and 50% styrene, being an amorphous thermoplastic material and highly impact resistant. Polyamide 6 (PA), known as Nylon 6, being a semi-crystalline thermoplastic that has high strength, toughness and impact resistance, showing good sliding behavior and good wear resistance; Polystyrene, (PS or styrene-butadiene-styrene), solid, transparent, hard and fragile, being an amorphous thermoplastic, highly resistant to impact. Regarding the GTR, with a particle size smaller than <200 μm, its content was verified by means of a TGA analysis, with 54% elastomers (36% natural rubber, and 18% styrene-butadiene), 29% of carbon black (CB) and 16% inorganic.

Preparation of the Compound

The recycled tire powders were dried in an oven at 100°C for 24 hours. Five samples of Polymer / GTR compound were prepared, varying the composition (5%, 10%, 20%, 40%, 50% and 70% GTR), for a single particle size (p <200μm). The mixing process was carried out with a Brabender mixing machine. Polymer / GTR laminates were obtained using a hot plate press at a constant pressure of 200 bar and different temperatures for 10 minutes, depending on the polymer to be treated. The samples for the test were prepared correctly in accordance with the specifications of Standard ASTM-D-638 type V. A sample of the pure polymer was also prepared with the same requirements for comparable results.

Microstructural Analysis

Scanning Electron Microscopy S.E.M. It was used to analyze the fracture surface of broken samples in stress-strain tests. It is possible to analyze the effects of this filler material on the matrix by observing the fracture surface of the polymer with the reinforcing particles. The images of the samples were analyzed according to the concentration of GTR. A JEOL 5610 microscope was used, and the samples were previously coated with a thin layer of gold in order to increase conductivity. The samples were photographed at 180 magnifications. The scanning electron microscope (MEB) is an instrument to obtain three-dimensional photographs because it has a high resolution and a great depth of field. In the photographs you can see the microstructure of microscopic samples. The SEM uses an electron beam instead of a light beam to form an image. It has a great depth of field, which allows a large part of the sample to be focused at the same time. In the scanning electron microscope, the sample is coated with a layer of carbon or a thin layer of a metal such as gold to give conductive properties to the sample.

Mechanical Analysis

The Tension-Deformation tests were performed with a Universal Instron 3366–10 kN machine, following the specifications of ASTM-D-638 Type V Standard. The test speed was 20 mm / min. The test temperature was 23 ± 2 ° C, and the relative humidity was 50 ± 5%. The study of mechanical properties, according to the concentration of GTR in the matrix and the size of the particles, includes the Modulus of Elasticity or Young’s, tensile strength, elongation at breakage and hardness or toughness. Five samples were used for each test.

Results And Discussion

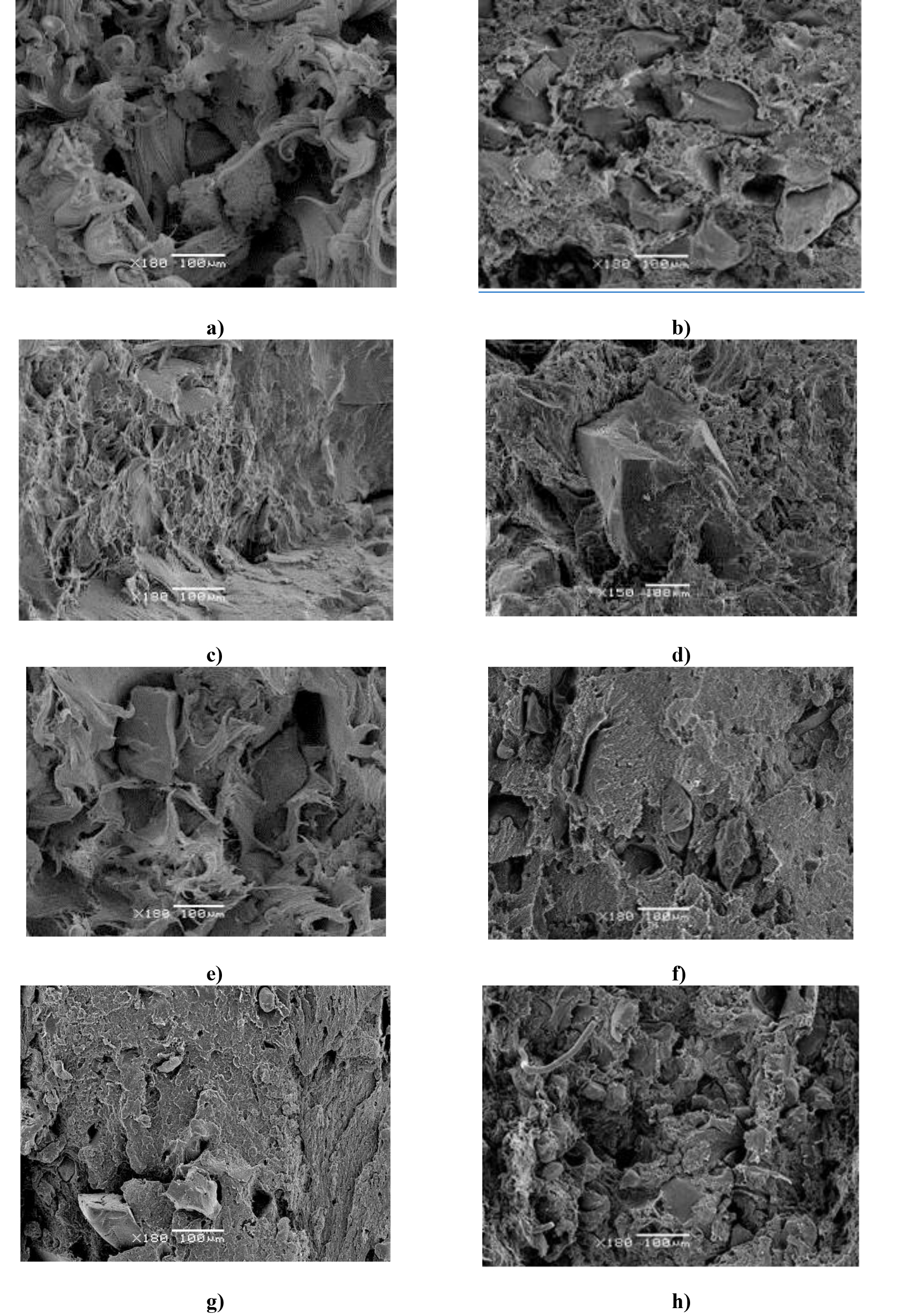

Structural Analysis: Scanning electron microscopy, S.E.M.

SEM photomicrographs of the fracture surface of the Polymer / GTR specimens of the Deformation-Traction test [Section 2.4] are shown in Figure 2. It is observed that the GTR particles do not reach their melting temperature when mixing with the different polymers analyzed, so that they are observed in the microphotographs, GTR particles dispersed in the homogeneous medium (matrix of the different polymers), while the polymer reaches its melting temperature, its dispersion being correct. The result is a microgranulated mass with a degree of dispersion that depends on the mixing time and temperature, which does not facilitate cohesion between phases, as can be seen in the different analyzed micrographs. Figures 2-a; 2-f and 2-g, shows compounds with low concentration of GTR (10%). It is observed that the particle of the reinforcement is integrated and covered practically by the matrix, showing a good interfacial adhesion. There are no gaps in the contour of the particle, and polymer fragments are dispersed over the entire surface of the particle by adhering to it. Figures 2-b, 2-d, 2-h, on the contrary, show compounds with high concentrations of reinforcement (40% -70% GTR), which causes an increase in faults and cracks in the matrix, worsening interfacial adhesion. In this case, the percentage of thermoplastic polymer is not sufficient to wrap the GTR particles, so that the joint is more difficult, cracks and pores of considerable size appearing in its contour. The GTR particles are clean and easy to extract, so the fracture has occurred through the interface of the matrix. On the other hand, with high concentrations of GTR there are greater possibilities of particle agglomeration, this agglomerate acting as a large particle.

Table 1. Main processing characteristics of the different polymers used

|

Polymer Type |

Commercial Name |

Density (kg/m3) |

Processing Temperature (ºC) |

Fusion Temperature (ºC) |

Press Temperature ºC) |

|

PVC |

Etinox |

1.225 |

195–200 ºC |

200 ºC |

210 ºC |

|

EVA |

Alcudia PA 539 type |

937 |

105–110 ºC |

110 ºC |

120 ºC |

|

HDPE |

Alcudia 4810-B |

960 |

150–155 ºC |

155 ºC |

170 ºC |

|

PA 6 |

Ultramid B3S |

1130 |

195–200 ºC |

220 ºC |

210 ºC |

|

ABS |

Terluran® HH-106 |

1050 |

180–185 ºC |

230 ºC |

195 ºC |

|

PP |

Isplen® 099 K2M type |

902 |

155–165 ºC |

165ºC |

165 ºC |

|

PS |

Polystyrol 486 M |

1050 |

180–185 ºC |

180°C |

195 ºC |

Figure 1. Scanning electron microscopy S.E.M., used for the Structural analysis of Polymer / GTR compounds. a) Scanning Electron Microscopy JEOL 5610. b) electrolytic coating machine (sputtering). c) Sample holder of the S.E.M., with the samples coated in a layer of 20 nanometers of gold.

Figure 2. SEM photomicrographs of the Polymers – GTR, for some concentrations of GTR particles in the polymer: a) EVA / GTR-10%; b) HDPE / GTR-40%; c) PA / GTR-20%; d) PVC / GTR-40%; e) PP / GTR-20%; f) ABS / GTR-10%; g) PS / GTR-10%; h) PS / GTR-70%

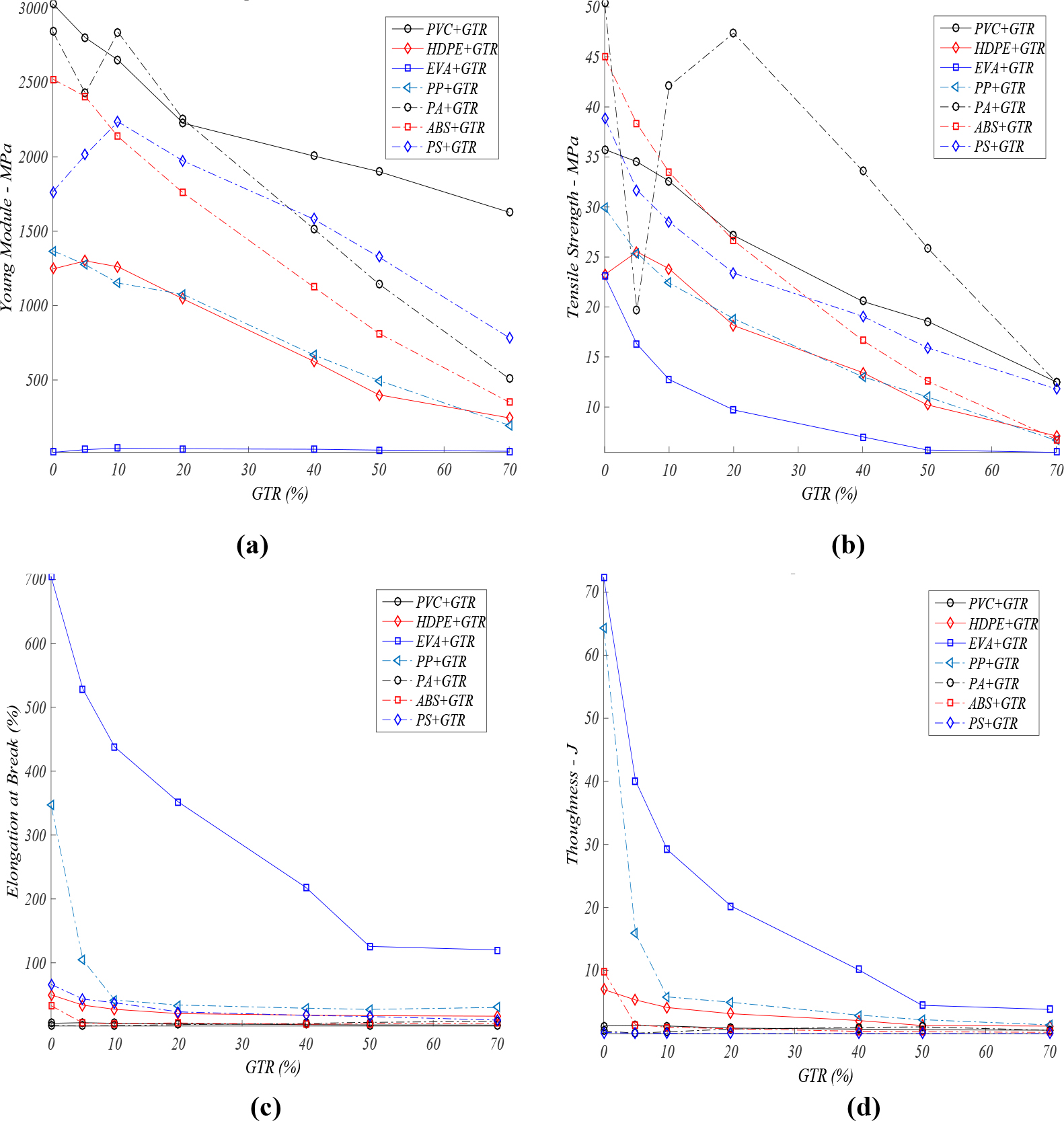

Results of Comparison Of Mechanical Properties

Through the Tension-Deformation test, the mechanical properties of the different polymers with different concentrations of GTR and size of reinforcement particles (p <200μm) in the polymer matrix have been analyzed. Regarding Young’s Module (Figure 3. a)), we can see how the compounds of EVA, HDPE and PS have a better performance with the addition of low percentages of GTR (5–10%) in the compound. In the rest of materials, generally, from the addition of GTR particles, Young’s Module worsens. A very clear case is the EVA copolymer, which has lower Young’s modulus properties and improves with the incorporation of GTR. In tensile strength (Figure 3. b)), we can see more evident decreases for concentrations greater than 10% of GTR, except for HDPE compounds, which exhibit better behaviors with the addition of quantities of GTR in low proportions (5–10% of GTR).

Regarding the elongation at break of the GTR compounds (Fig. 3. c)), the highest level is for the EVA compounds, which range between 700% and 350%, for 0% GTR concentrations. to 20% respectively. The reduction of the deformability of the elastomer influences the decrease in elongation and, subsequently, the decrease in hardness, showing similar behaviors in terms of hardness for compounds with EVA / GTR. The decrease in elongation at break is related to imperfect interfacial adhesion between the components, as discussed previously in section 3.1. The incidence of poor adhesion between phases is a particularly important result. Elongation at break with the addition of GTR particles decreases dramatically, rising only in the case of PA, with the addition of GTR. Regarding the tenacity (Figure 3. d)), these falls are even greater. The toughness ranges decrease for concentrations of 10% GTR. From the observation of the comparative graphs of tenacity (J) it can be seen that, the ones with the greatest energy to produce the fracture are EVA and PP. For EVA or PP that add 10–20% GTR, the breakage energies of the compound decrease significantly. For PP, ABS and, to a lesser extent, HDPE, the addition of GTR negatively affects the properties of tear strength (J). A very prominent case is the PVC and PA polymers, which show very low breaking energy values for the pure polymer and improve this property (strength) with the addition of the percentage of GTR in the polymer matrix.

Figure 3. a) Young’s modulus (MPa), b) Tensile strength (MPa), c) Elongation at break (%), d) Tenacity or hardness (J), for the seven Polymer / GTR concentrations and particle sizes p <200μm.

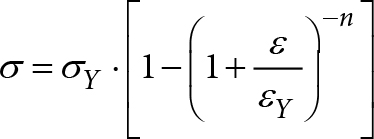

A deeply Comparative-Analysis Stress-Strain model is needed, for a further research we can obtain curves obtained from the test of the polymers mixed with the full range of GTR concentrations. In this case, the complex morphology of the matrix polymer blended with GTR particles does not allow the use of the standard elastoplastic equations or the classical approach. For this reason, and in the same way as purposed [22], a simple uniaxial tensile stress–strain relation is proposed, based on three parameters, σY, εY, and n, where σY is the yield strength and εY the elongation at yield.

[1]

[1]

Conclusions

There are necessary for a deep analysis of the compounds analyzed, through DSC, Differential Scanning Calorimetry, that allows the study of those processes in which enthalpic variation occurs, for example determination of specific calories, boiling points and fusion, purity of crystalline compounds, reaction enthalpy and determination of other first and second order transitions. The calorimetry applied to the composite materials is used as a tool to detect the possible changes in the crystallinity and microstructure of the matrix by adding a second component as a reinforcement [23–24]. By measuring the melting temperatures and enthalpy of the compounds, these changes can be analyzed through DSC analysis. The thermal behavior of the compounds can be studied using DSC, the final thermogram (heat / temperature flow) is obtained. The melting point of the sample and the glass transition temperature can be obtained to determine the modification of the internal structure of the matrix and possible reactions that may occur in the mixture. So, in this sense can be an interesting analysis for further research.

Comparatively, it can be deduced from the observation of the results of HDPE, PVC, EVA, PP, PA, ABS and PS with GTR, that the analyzed mechanical properties of the compounds may have some significant changes depending on the amount of GTR that is supplied to the polymer matrix, that is, some properties vary according to the percentage of GTR added. As can be seen in section 3.2, generally the highest property values correspond to the pure polymer (0% GTR). Thus, for EVA, HDPE, PA and PS, some mechanical properties are improved by the addition of microparticles (p <200 µm) of GTR in the polymer matrix. With low concentrations of GTR (5–10%), the Young’s Modulus of the compound increases, although other mechanical properties decrease as with the compounds of EVA, PS and HDPE. This behavior may be due to the fact that the reinforcement matrix is correct for these formulations (as shown in section 3.1 of this investigation) and, therefore, some mechanical properties improve. However, for GTR concentrations greater than 10%, all mechanical properties decrease, except for PA compounds. The results obtained from the analysis of these compounds show the limit concentration of GTR in order to maintain acceptable values of the mechanical properties is of the order of 5–10% in general, values that would allow its use in various fields of industry with mechanical solicitations not too high, giving out disused amounts of GTR, as other authors have studied before, GTR compounds can be reused with other applications [25–26]. At a structural level we see a clear relationship between structural properties and mechanical properties, relating the compounds that show better internal cohesion (Section 3.1), compounds with low proportions of GTR (10%) and that coincide with the compounds that have better mechanical properties. Likewise, with high concentrations of GTR (from 40% to 70% GTR), we see how the mechanical-structural properties progressively worsen with the addition of percentages of GTR, as the photomicrographs performed at 180 magnifications with electron microscopy show. What clearly reveals the structural study is that the interaction between the polymeric matrix with the GTR particles is very weak and low

Financing: This research was funded by the MINISTRY OF ECONOMY AND COMPETITIVENESS, Government of Spain ENE2015-64117-C5-3-R (MINECO / FEDER).

Conflicts of Interest: The authors declare no conflict of interest.

References

- European Tyre Recycling Association (ETRA). www.etra-eu.org (accessed aug 14, 2018)

- Used Tyre Working Group (UTWG). Tyre Recycling; Department of Trade and Industry: London, UK. www.tyredisposal.co.uk (accessed novembrer 18, 2006).

- Liu HS, Richard CP, Mead JL and Stacer RG. Development of Novel Applications for Using Recycled Rubber in Thermoplastics. Technical Research Program. Chelsea Center for Recycling and Economic Development, University of Massachusetts: Lowell, 2000.

- Figovslq O, Beilin D, Blank N, Potapo J and Chernyshe V. Development of polymer concrete with polybutadiene matrix. Cem Concr Compos. 1996, 18, 437–444.

- Hernandez-Olivares F, Barluenga G, Bollatib M and Witoszekc B. Static and dynamic behaviour of recycled tyre rubber-filled concrete. Cem Concr Compos. 2002, 32, 1587–96.

- Goncharuk GP, Knunyants MI, Kryuchkov AN and Obolonkova ES. Effect of the specific surface area and the shape of rubber crumb on the mechanical properties of rubber-filled plastics. J Polym Sci Part B: Polym Chem. 1998, 40, 166–169.

- Dierkes WK. Rubber recycling. In Recent research developments in macromolecules, Pandalai SG, Ed.; Trivandrum: Research Signpost, 7, 265–292, 2003.

- Radeshkumar C and Karger-Kocsis J. Thermoplastic dynamic vulcanisates containing LDPE, rubber, and thermochemically reclaimed ground tyre rubber. Plast Rubber Compos. 2002, 31, 99–105.

- Yehia A, Mull MA, Ismail MN, Hefny YA and Abdel-Bary EM. Effect of chemically modified waste rubber powder as a filler in natural rubber vulcanizates. J Appl Polym Sci. 2004, 93, 30–36.

- Colom X, Andreu-Mateu F, Cañavate FJ, Mujal R and Carrillo F. Study of the influence of IPPD on thermo-oxidation process of elastomeric hose. J Appli Polym Sci. 2009, 114, 4, 2011–2018.

- Cepeda-Jimenez CM, Pastor-Blas MM, Ferrándiz-Gómez TP and Martín-Martinez JM. Surface Characterization of vulcanized Rubber treated with sulphuric acid and its adhesion to polyurethane adhesive. J Adhesion. 2000, 73, 135–160.

- Mujal R, Marín-Genescà M, Orrit J, Rahhali A, Colom X, Dielectric, mechanical, and thermal characterization of high-density polyethylene composites with ground tire rubber. Journal of thermoplastic composite materials. 2012, 25, 5, 537–559

- Mujal, R.; Orrit J., Ramis, X.; Marin-Genesca, M.; Rahhali, A. Study on dielectric, mechanical and thermal properties of polypropylene (PP) composites with ground tyre rubber (GTR). Polymers & Polymer Composites (ISI). 2012, 20, 9.

- Mujal, R.; Ramis, X.; Orrit-Prat, J; Marin, M. Study on dielectric, thermal, and mechanical properties of the ethylene vinyl acetate reinforced with ground tire rubber. Journal of Reinforced Plastics and Composites0. 2011, 30, 7, 581–592

- Mujal R, Orrit-Prat J, Ramis-Juan X, Marin-Genesca M. Electrical application of polyamide reinforced with old tire rubber (ground tire rubber): Dielectric, thermal, mechanical and structural properties. Journal of thermoplastic composite materials. 2014. 27, 9, 1209–1231

- Nakason C, Kaesaman A and Supasanthitikul P. The grafting of maleic anhydride onto natural rubber. Polym Test. 2004, 23, 35–41.

- La Mantia FP, Lo Verso S and Tzankova Dintcheva N. EVA Copolymer Based Nanocomposites. Macro Mat Eng. 2002, 287, 12, 909–914.

- Kim JI, Ryu SH and Chang YW. Mechanical and dynamic mechanical properties of waste rubber powder/HDPE composite. J Appl Polym Science. 2000, 77, 2595–2602.

- Markov A., Fiedler B., Schulte K. Electrical conductivity of carbon black/fibres filled glass-fibre-reinforced thermoplastic composites. Composites Part A: Applied Science and Manufacturing. 2006, 37, 9, 1390–1395

- J.R. Pothnis , M. Sridevi, M.K. Supreeth , A.R. Anilchandra, G. Hegde, S. Gururaja. Enhanced tensile properties of novel bio-waste synthesized carbon particle reinforced composites. Materials Letters 251 (2019) 110–113.

- Saad ALG, Aziz HA and Dimitry OIH. Studies of Electrical and Mechanical Properties of Polyvinyl chloride) Mixed with Electrically Conductive Additives. J Appl Polym Science. 2004, 91, 1590–1598.

- Giroud, J.P. Mathematical model of geomembrane stress-strain curves with a yield peak. J. Geotext. Geomembr. 1994, 13, 1–22.

- N. Aini Fauziyah , A. Rosyidy Hilmi, M. Zainuri, M. Zainul Asrori, M.i Mashuri, M. Jawaid, S. Pratapa. Thermal and dynamic mechanical properties of polyethylene glycol/quartz composites for phase change materials. J. APPL. POLYM. SCI. 2019, DOI: 10.1002/APP.48130

- A. A. Gadgeel , Shashank Tejrao Mhaske. Novel approach for the preparation of a compatibilized blend of nylon 11 and polypropylene with polyhydroxybutyrate: Mechanical, thermal, and barrier properties. J. APPL. POLYM. SCI. 2019, DOI: 10.1002/APP.48152

- Colom X., Cañavate J., Carrillo F. Structural and mechanical studies on modified reused tyres composites. Eur Polym Journal. 2006. 42. 2369–2378.

- Kim JI, Ryu SH and Chang YW. Mechanical and Dynamic Mechanical Properties of Waste Rubber Powder/HDPE Composite. J. Appl. Polym. Science. 2000, 77, 2595–2602.